East Coast Yacht Training & Transport 585-721-6236

East Coast Yacht Training & Transport 585-721-6236

East Coast Yacht Training & Transport 585-721-6236

East Coast Yacht Training & Transport 585-721-6236

Modern proportional thrusters provide precise, predictable control — improving docking performance, reducing stress, and supporting advanced systems like Dockmate and Avikus.

Properly sized bow and stern thrusters are critical to safe and predictable docking, especially in wind or current. East Coast Yacht specifies and installs Sleipner and Side-Power thrusters based on vessel displacement, windage, and usage, not just tunnel size. This approach ensures usable thrust, proportional control, and long-term reliability.

Sleipner and Side-Power thrusters are manufactured by Sleipner, a long-established supplier of bow and stern thruster systems for yachts and commercial vessels.

Dual joystick for hydraulic thrusters with variable speed control and hold-feature.

The intelligent LCD panel displays real-time information such as the amount and direction of thrust, remaining run time, oil temperature, and pressure read-out.

Supports retractable thrusters with or without variable speed control. Read more about the significant product features below.

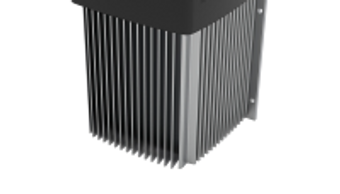

The E100 is a highly efficient, compact, lightweight thruster suitable for boats between 35-55 feet. The integrated inverter for variable speed control makes for a quick and easy installation.

E100 has the new 6-phase PMSM synchronous motor made explicitly for marine thruster use, delivering performance and runtime never seen before in a DC thruster.

Previous Sleipner thruster models can be upgraded with the new E-series electric motor either directly or by utilizing an adapter plate between the bracket and motor.

Modern bow and stern thrusters are no longer simple on/off devices. Proportional thruster systems allow precise control of thrust, enabling smoother corrections, better station keeping, and reduced stress during docking.

Older on/off thrusters deliver full power instantly, which can lead to overcorrection, increased wear, and inconsistent results — especially in wind or current.

Thrusters play a critical role in close-quarters maneuvering by allowing controlled lateral movement independent of propulsion. When properly sized and configured, they provide predictable response and fine adjustment during docking.

Inconsistent thrust, delayed response, or excessive power delivery can make docking more difficult instead of easier — particularly on heavier or high-windage vessels.

Proportional control allows you to apply only the thrust you need, making small adjustments without overcorrecting during close-quarters maneuvers.

Consistent, predictable thrust improves station keeping and lateral control, especially on heavier vessels or boats with high windage.

Smooth power delivery reduces shock loads on components and minimizes abrupt movements, improving both handling confidence and long-term reliability.

Many vessels are still equipped with older on/off thruster systems that were adequate when installed but no longer match modern handling expectations. These systems deliver full power instantly, increasing component wear and making fine control difficult.

Upgrading to modern proportional thrusters improves reliability, reduces mechanical stress, and provides smoother, more predictable response — especially when integrated with advanced control systems.

Thruster performance depends on proper sizing, tunnel configuration, electrical supply, and vessel characteristics. Oversized or undersized systems can perform poorly, draw excessive power, or create unnecessary mechanical stress.

Correct installation ensures the thruster delivers usable thrust efficiently, integrates properly with helm controls, and performs consistently in real-world docking conditions.

Thruster upgrades are most effective on vessels where docking precision, control, and reliability are operational priorities. Suitability depends on vessel configuration, existing systems, and how the boat is typically operated.

We evaluate each vessel individually and recommend upgrades only when they provide a meaningful improvement in handling and reliability.

Thruster performance and upgrade options depend on vessel characteristics, existing systems, and how the boat is operated. We’ll review your setup and recommend the right solution — no unnecessary upgrades.

The following questions address common considerations when evaluating docking and maneuvering systems.

Please reach us at captainparks01@gmail.com if you cannot find an answer to your question.

Side-Power is a premium line of bow and stern thrusters manufactured by Sleipner, a Norwegian company recognized globally for high-performance marine maneuvering systems. Side-Power thrusters are engineered for reliability, proportional control, and seamless integration with modern yacht control systems.

E-Vision systems offer:

They are especially well suited for larger or heavier vessels.

In many cases, yes. Proportional thrusters provide smoother, more predictable control and reduce mechanical and electrical stress compared to full-power on/off systems.

Not necessarily in raw thrust alone, but they are more effective. Because E-Vision thrusters deliver smoother, proportional power and can sustain thrust longer without overheating, they provide better real-world control, particularly in wind or current.

A larger thruster can draw more current at full output. However, when properly sized:

Correct sizing is about control and efficiency, not simply maximum power.

In many cases, yes. One advantage of the E-Vision line is that stepping up one size may still fit within the same tunnel diameter, avoiding fiberglass work. Each vessel must be evaluated to confirm compatibility.

Yes. Most modern Side-Power systems offer true proportional control, allowing precise thrust application rather than simple on/off operation. This is critical for:

Yes. Side-Power thrusters integrate exceptionally well with Dockmate systems, including proportional control and advanced features such as DPS (Dynamic Positioning). Proper configuration and calibration are essential to achieve smooth and predictable performance.

Thruster sizing is based on more than boat length. Key factors include:

Incorrect sizing is one of the most common causes of poor thruster performance.

Typical timelines:

Actual timelines depend on vessel complexity and system configuration.

High-performance thrusters benefit from:

In some cases, battery or charging upgrades are recommended to ensure reliable performance.

Yes. Side-Power thrusters have an excellent reputation for reliability when:

Most issues arise from undersizing, poor installation practices, or inadequate electrical support.

Yes. Thruster performance is only as good as the operator’s understanding. Training includes:

To evaluate and quote correctly, we typically need:

This information allows us to recommend the correct solution, not just a replacement.

Final thruster selection, sizing, and installation approval are always handled through direct consultation. This ensures safety, reliability, and correct system performance.